With more and more stringent regulatory standards, developing regions that offer growth opportunities and a higher demand for mechatronics & pharmaceuticals, the number of requested cleanrooms in the field keeps increasing.

Although the market is slightly dominated by the electronics/semiconductor industry, the demand for cleanrooms used in biopharmaceutical facilities continues to grow over the last few years as well. Within the pharmaceutical segment, the following main categories are identified: drug development, biopharmaceutical production and cell & gene therapy. The cell & gene therapy market accounts for the lowest share due to the novelty of this area in combination with cleanrooms serving pre-clinical/clinical manufacturing purposes only. However, this does not mean that the cell & gene therapy category doesn’t see the most rapid growth. But what type of cleanroom fits best?

At ABN Cleanroom Technology, we experience that configure-to-order cleanrooms are still taking the lead in our range of cleanroom solutions, followed by assemble-to-order cleanrooms and prefabricated ready-to-ship cleanrooms. However, there is definitely an ongoing trend for increased assemble-to-order and prefabricated cleanrooms, as both the semiconductor and pharmaceutical industry realize the technological and operational advantages of these cleanroom solutions.

The rise in modular and assemble-to-order cleanrooms is due to an increasing preference for more adaptability and scalability of the production area and the industry recognizing problems with stick-built solutions. A lack of flexibility and speed, together with a total cost of operation that is way too high are unfortunately characteristics of stick-built cleanrooms.

Prefabricated cleanrooms currently have and will increasingly see the highest growth among different cleanroom technology segments. In some cases, such as temporary pharmaceutical manufacturing facilities, there is little choice other than assemble-to-order or ready-to-ship cleanroom solutions.

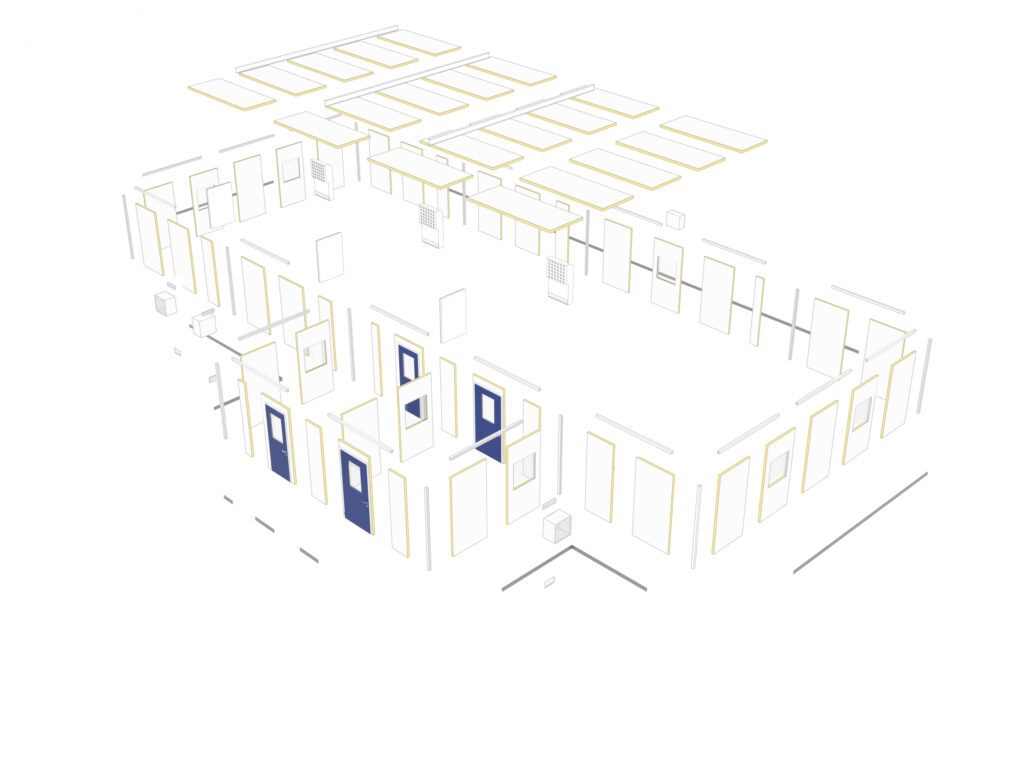

The cost effectiveness of pre-engineered cleanrooms largely varies based on the required space, functionalities, validation activities and documentation specifications. With this type of cleanrooms, standardized building blocks are provided and can be configured to create any design. This pre-engineering approach results in a variety of cleanrooms solutions, such as prefab container-based solutions. Prefabricated cleanroom design is accomplished by engineers in a factory environment. Field installation labour costs are reduced and controlled conditions in a manufacturing plant generally deliver higher quality and reproducible results that exceed quality results obtained by traditional stick-built cleanrooms.

Our ready-to-ship cleanroom units are built off-site, meaning that delivery times and local process interruption are kept to a minimum. This method delivers precise and fully compliant cleanroom systems without neglecting flexibility, adaptability and scalability.

Criteria that influence the selection of ready-to-ship cleanrooms, assemble-to-order cleanrooms and configure-to-order cleanrooms can be:

Predefined building blocks make it easy to integrate the latest Industry 4.0 and IIoT technologies into these cleanrooms. Continuous connectivity with our cleanrooms enables us to collect data on the efficiency and use of the cleanroom and to act immediately when something threatens to happen. By doing this, we can optimise the life cycle of the cleanroom. On top of that, Industry 4.0 connected cleanrooms enable a smart maintenance & service approach providing continuous insights in your cleanroom’s use and parameters.

More and more companies from various industries are recognising the benefits of a modular cleanroom approach. Not only in terms of lead-time, but also in terms of cleanroom quality, since all components are predefined, positive results are being achieved. As the market leader in pre-engineered and modular cleanroom design, we are very pleased with this trend and hope to provide many more companies with one of our pre-engineered solutions in the coming years.

Legolisation means standardisation. Standardisation causes a shift in production. Work is carried out in conditioned spaces such as factory halls. our cleanrooms are manufactured partly or entirely off-site, which means huge savings on transport costs and reduction of inconvenience on-site