Off-the-shelf cleanrooms

Fast deployment, proven reliability

To meet the unique demands of different industries, we have developed a range of standardized cleanroom solutions, each designed to align with specific market requirements. Whether for pharmaceutical, biotech, semiconductor, or high-tech manufacturing applications, our ready-to-ship products ensure a seamless fit. By combining modular design, rapid deployment, and proven reliability, we help businesses scale efficiently while maintaining the highest cleanroom standards.

At the core of our approach is ADAPTUS, a methodology that allows us to combine different building blocks to create flexible, scalable cleanroom solutions. By leveraging modular components and pre-engineered designs, we can quickly adapt to specific project needs while maintaining efficiency, consistency, and high performance. This approach ensures seamless integration, faster implementation, and long-term adaptability, making our cleanrooms a future-proof investment.

Our solutions

At ABN Cleanroom Technology, we know that every industry demands a unique approach to contamination control and environmental precision. Our productised cleanroom solutions are engineered to meet all the required standards. Explore our tailored cleanroom environments, each designed with specific features to ensure optimal performance, quality, and compliance in your industry.

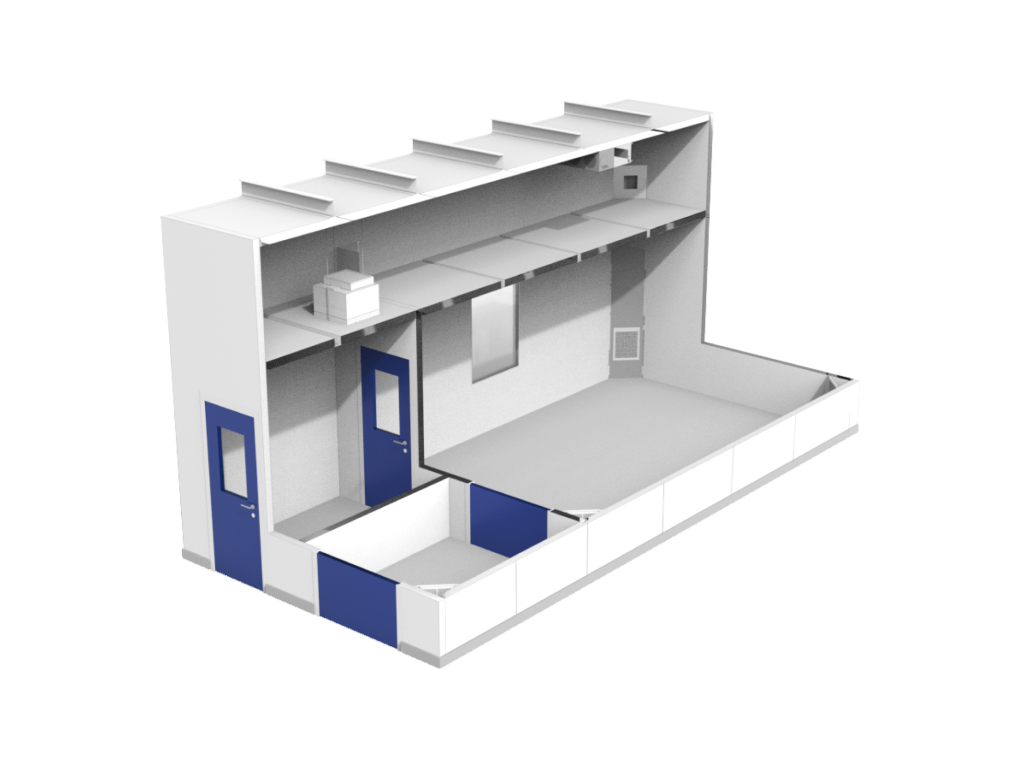

ICONIC addresses the growing demand for quick and efficient cleanroom solutions, serving as the ideal entry-level cleanroom for a wide range of applications.

Classifications

Up to ISO6

Location

Indoor

Price range

Delivery times

6-8 weeks

INTEGRA is a modular, off-the-shelf cleanroom solution meeting ISO and cGMP standards through the integrated VIX concept.

Classifications

Up to ISO5

Up to cGMP B

Location

Indoor

Price range

Delivery times

10-15 weeks

The SoftCube is a freestanding, mobile filtration unit available in a range of dimensions. Its sidewalls can be configured with either flexible PVC curtains or rigid PVC panels. Thanks to its modular design, the SoftCube can be delivered within just 4 weeks.

Classifications

Up to ISO7

Location

Indoor

Price range

Delivery times

4-6 weeks

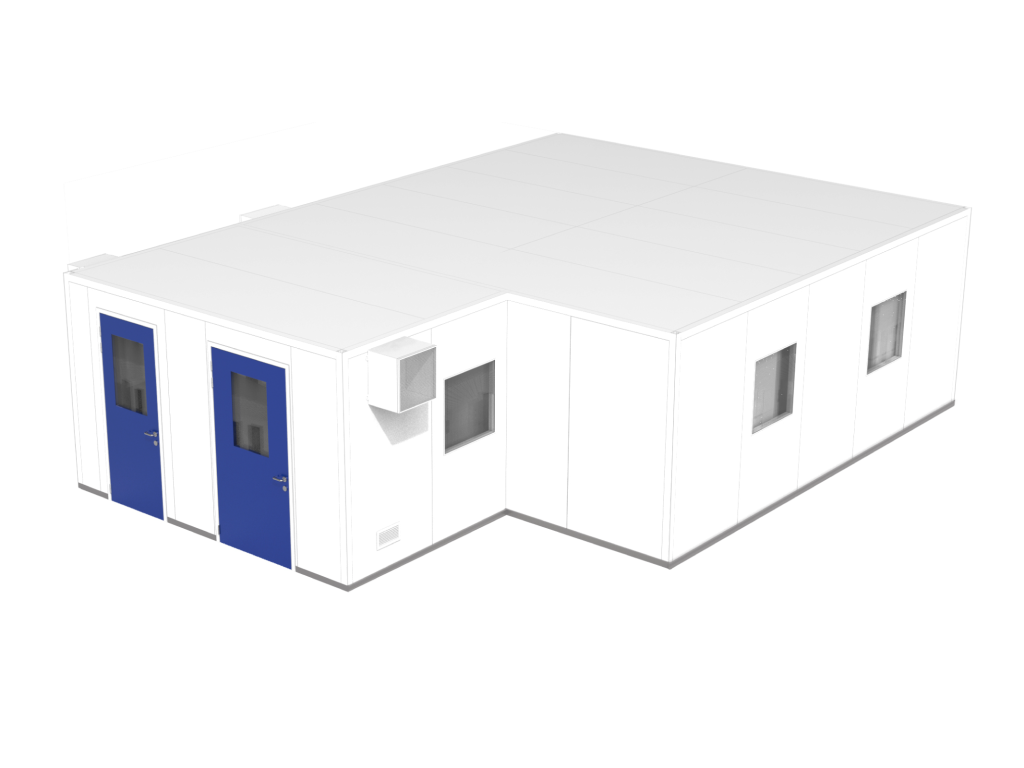

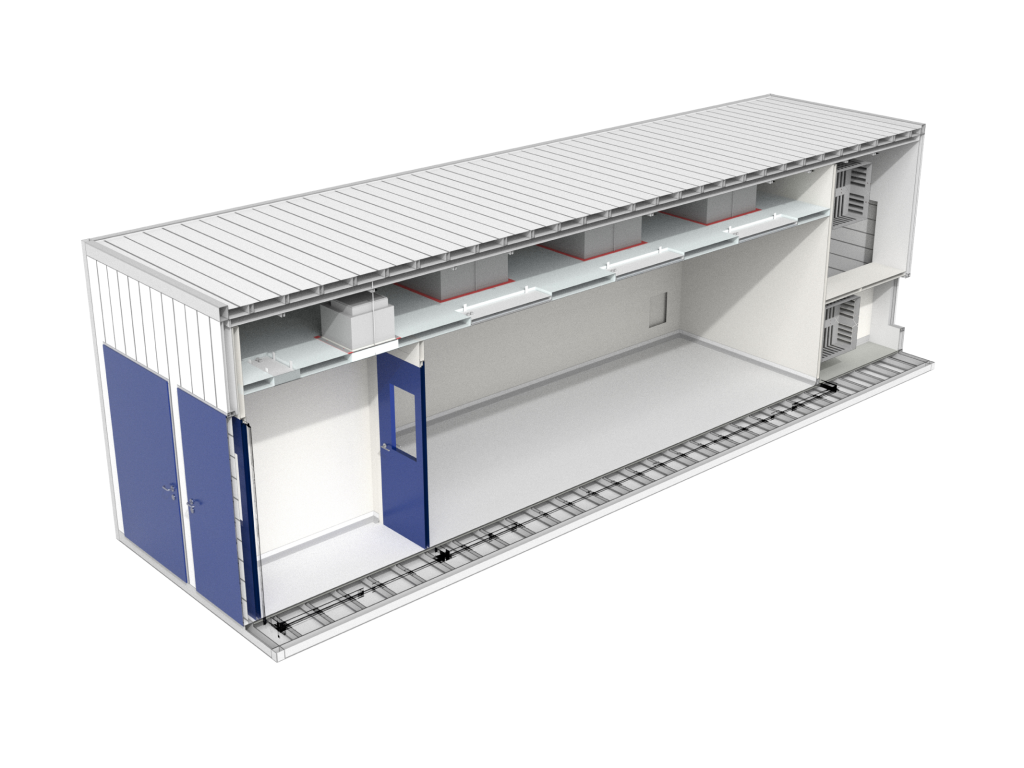

SteriCube ONE is a modular outdoor cleanroom unit, ideal for controlled environments when indoor space is limited.

Classifications

Up to ISO5

Up to cGMP B

Location

Outdoor

Price range

Delivery times

12-16 weeks

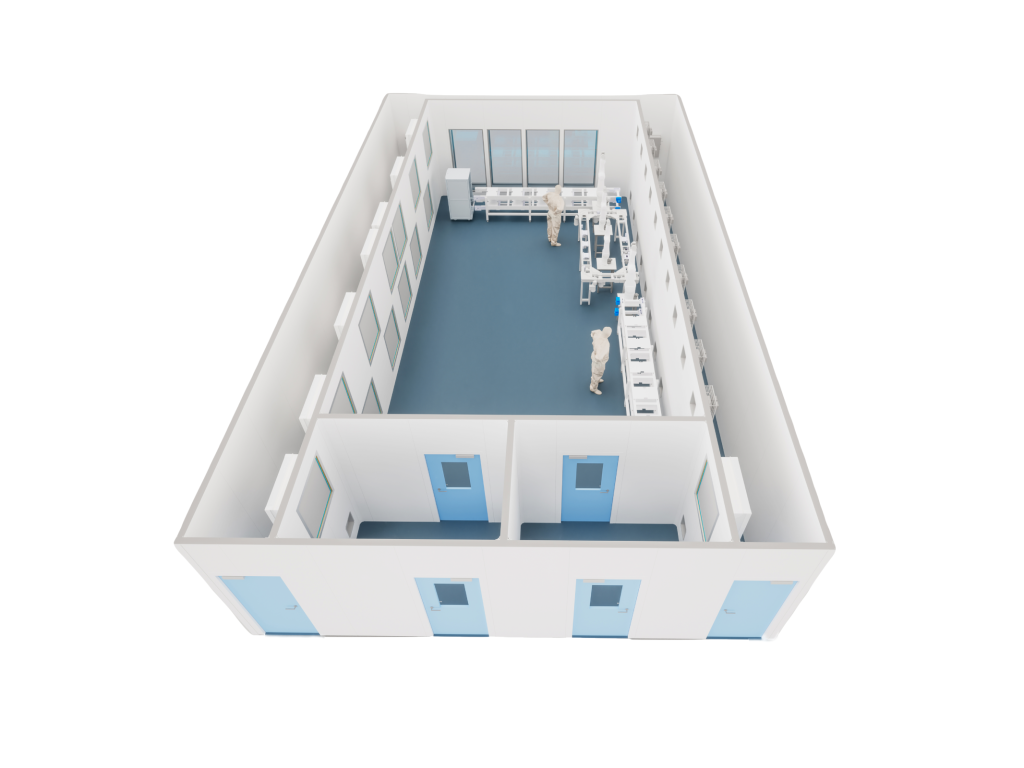

SteriCube VELOX is a scalable outdoor cleanroom solution, combining multiple SteriCube ONE units to create large, high-performance classified environments.

Classifications

Up to ISO5

Up to cGMP B

Location

Outdoor

Price range

Delivery times

14-18 weeks

The MATRIX is a VIX cleanroom with side-mounted plenums, designed for facilities with limited ceiling height while maintaining optimal airflow and contamination control.

Classifications

Up to ISO5

Up to cGMP B

Location

Indoor

Price range

Delivery times

10-14 weeks

Industry-specific cleanroom solutions

In addition to our standardized off-the-shelf products, our ADAPTUS platform enables us to design industry-specific cleanroom solutions using a flexible system of standardized building blocks. This approach allows us to combine the efficiency of modular construction with the freedom to tailor each project to the specific needs of the customer. Whether it’s for cell and gene therapy, hospital pharmacies, or other critical environments, we create cleanrooms that meet industry requirements while remaining fully customer-specific.

DRYCELL

The DRYCELL is a modular dryroom solution designed for ultra-low humidity environments, ensuring precise climate control for sensitive production processes.

HOSPIX

The HOSPIX is a specialized cleanroom solution for hospital pharmacies, designed to ensure PIC/S-compliant medication compounding in a controlled environment.

GENEFAB

GENEFAB is a specialized cleanroom solution for cell and gene therapy production, ensuring GMP compliance and controlled biomanufacturing conditions.

Our industries

High-Tech

Life Sciences

Pharma

Manufacturing

Food processing

Battery

Speeding up cleanroom solutions through smart configuration

The Adaptus Cleanroom Product Platform is a modular, pre-engineered cleanroom solution designed for flexibility, efficiency, and scalability. Built on a standardized yet adaptable framework, it allows businesses to easily configure cleanroom environments to meet their specific industry requirements—whether for pharmaceuticals, biotech, semiconductors, or other high-tech applications.

Speed without compromise

ADAPTUS ensures rapid delivery and seamless installation, getting your cleanroom up and running in record time without sacrificing quality.

Highly cost-efficient

Designed for cost efficiency, ADAPTUS delivers high-performance cleanroom solutions without unnecessary expenses, maximizing your investment.

Plug-and-Play modularity

Our smart building blocks allow for a hassle-free, modular approach, making cleanroom construction as simple as stacking high-tech LEGO.

Future-proof scalability

Need more space or an upgrade? ADAPTUS grows with you, offering unmatched flexibility for evolving production demands.

Ai-powered intelligence

Smart AI integration enhances operational efficiency, ensuring real-time monitoring, predictive maintenance, and optimal performance.

Engineered for excellence

Built for high-performance applications, ADAPTUS guarantees top-tier cleanliness, airtightness, and reliability.

What our clients say

Start your cleanroom project online

Leading companies across Europe trust ABN Cleanroom Technology for pre-engineered cleanroom solutions. Our innovative facilities are designed for those who want to make a difference. Get a no-obligation price estimate or learn more about our pre-engineered cleanrooms by filling in the form below. Our team will get in touch within one working day.

Let's talk cleanrooms

Whether you’re looking for expert advice, a quick answer, or a detailed discussion, we’re here to help. Choose the option that works best for you—call us directly, send us an email, or book a 30-minute meeting at your convenience. Let’s find the best cleanroom solution together!

E-mail us

info@abn-cleanroomtechnology.com

Call us

+32 (0)89 32 10 80

Book a meeting

Book a 30 minute meeting

Where you can find our productised cleanroom solutions