Sustainability within CTO+

Low-energy cleanrooms for minimized operational expenditure (OPEX)

We configure sustainable cleanroom solutions with high-efficiency components and data-driven controls to guarantee minimal energy consumption which is impossible in traditional cleanroom approach.

The problem with traditional cleanrooms

Traditional cleanroom design leads to immense long-term operating costs and unnecessary environmental impact.

- High Energy Consumption: Cleanrooms are notorious energy consumers. using up to 25 times more energy than standard commercial buildings. The Heating, Ventilation, and Air Conditioning (HVAC) system is the main energy consumer in a cleanroom, often accounting for up to 90 percent of total electricity use.

- Inefficient Airflow: Traditional cleanrooms rely on large air handling units that move air over long distances through complex ductwork, resulting in high pressure losses and wasted energy.

- High Life Cycle Costs (LCC): Traditional systems rely on VAV dampers, which limit energy-saving strategies such as night setback operation and lead to significantly higher energy use compared to the precise, dynamic control provided by our patented VIX system.

Our solution: Patented technologies driving energy-efficient cleanroom (VIX, DSI, DFA)

We design superior energy efficiency and sustainability directly into every modular cleanroom using our advanced, configured approach. Our highly energy-saving, patented VIX concept is central to this commitment, ensuring the lowest environmental impact and optimal operational performance.

How we drive energy efficiency

- Dynamic air control: Our DFA continuously monitors particle levels. Based on the measured particle concentration, the number of air changes in the cleanroom can be reduced, resulting in significant energy savings.

- Superior airtightness: Because we do not use VAV valves in our VIX system, we can reliably achieve L2 or L3 airtightness levels.

Circularity: At ABN, we consider PFAS-free design part of the Olympic Minimum. By using R32 as the standard refrigerant in our cooling systems, and enabling the use of R290 (propane) with a significantly lower Global Warming Potential (GWP), we support more circular and sustainable cleanroom solutions.

Your competitive advantage

Our configured solution delivers clear, quantifiable benefits in sustainability and cost management:

Advantage for you

Mechanism

Impact

Maximized energy savings and lowest life-cycle cost

Patented VIX concept

Up to 50% reduction in energy use and lower total life-cycle cost, including reduced operating expenses (OPEX)

Higher ranking in sustainability reports

PFAS-free cooling solutions

Lower Global Warming Potential (GWP) of the cooling system

A more sustainable approach

Circular design principles

Improved recyclability of materials

Choose your configuration

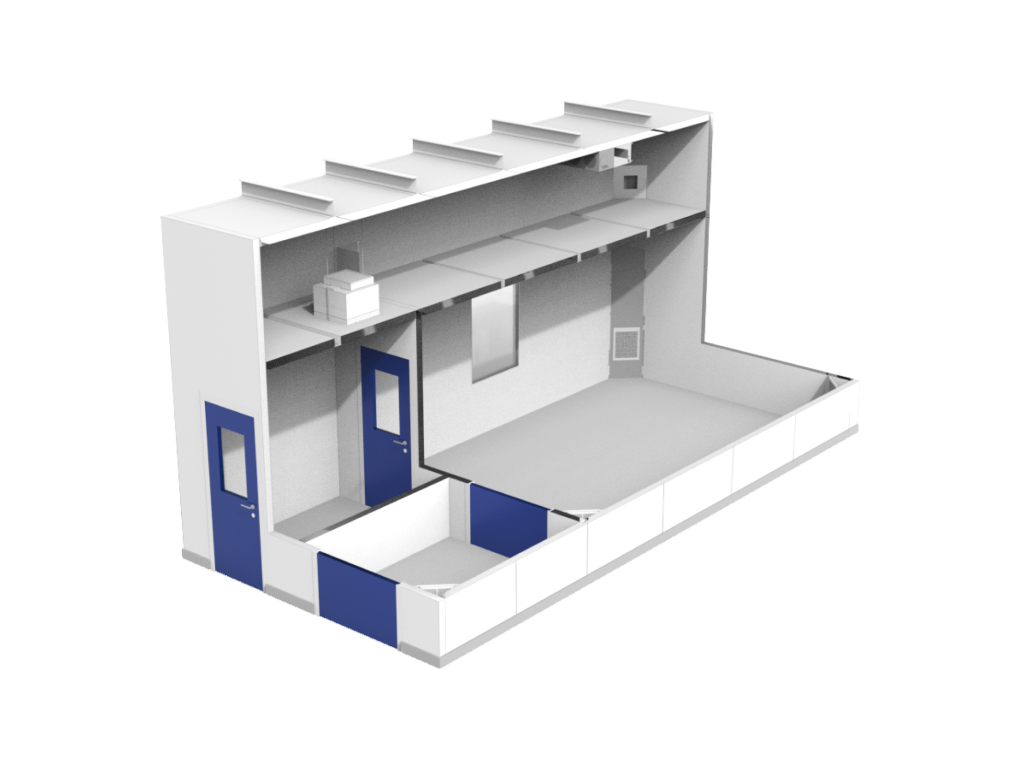

INTEGRA is a modular, off-the-shelf cleanroom solution. It meets ISO and cGMP standards through the integrated VIX concept. Moreover, it provides strong compliance without long lead times.

Classifications

Up to ISO5

Up to cGMP B

Location

Indoor

Price range

Delivery times

10-15 weeks

The VIX concept is an integrated airflow and plenum solution designed to ensure ISO and cGMP compliance. It combines high performance with energy efficiency, providing reliable cleanroom conditions without complex construction or long lead times.

Classifications

Up to ISO 4

Up to cGMP A

Location

Indoor

Price range

Delivery times

16 weeks

Energy-efficient patented VIX-concept

Go as you grow

Let your business evolve rapidly with VIX. Today, you might need a small dimensioned cleanroom, while next week, it must be enlarged due to increasing business.

99,9% uptime

VIX is characterized by its decentral air systems. These air units are installed in the airtight plenum above the cleanroom and guarantee a 99,9% uptime.

Upgradable

The performance of VIX cleanrooms (patent nr. 2820356) can be easily ISO classification upgraded and modified towards your changing cleanroom business.

Start your cleanroom project

Tell us about your cleanroom requirements and specifications, and we’ll prepare a first cost estimation for you within one working day. Simply complete the form with as much detail as possible, from classification and size to specific industry or technical needs.

Prefer to speak directly? You can always contact us by phone or email, and our team will be happy to discuss your project.

FAQ

The most frequently asked questions about our custom cleanroom solutions.

What makes a cleanroom “energy-efficient”?

An energy-efficient cleanroom achieves the required cleanliness level while using less fan power and fewer air changes than traditional designs. The biggest levers are airflow strategy, pressure stability, airtightness, and how precisely the system adjusts air and filtration to real conditions.

Why do cleanrooms consume so much energy?

Cleanrooms consume a lot of energy mainly because HVAC must continuously move and filter large air volumes to maintain cleanliness, temperature, humidity, and pressure. In many facilities, HVAC is the dominant electrical load because fans run continuously and air is heavily conditioned.

How does your approach reduce cleanroom OPEX?

We reduce OPEX by configuring the cleanroom with high-efficiency components and control strategies that avoid unnecessary airflow and pressure losses. Lower fan energy, smarter operating modes such as night setback, and stable pressure control typically drive the largest operational savings.

What is Dynamic Air Control and why does it reduce energy use?

Dynamic Air Control adjusts the supplied air and filtration based on actual conditions rather than fixed “worst-case” settings. By monitoring the cleanroom and providing only what is required to stay within specifications, the system avoids over-ventilating and wasting fan energy.

How does airtightness improve energy efficiency in a cleanroom?

Airtightness reduces leakage, which helps maintain pressure with less airflow. When the envelope is well sealed, the HVAC system does not need to compensate for uncontrolled air loss, which lowers fan power and stabilizes performance.

What is night setback, and when can it be used in cleanrooms?

Night setback is an energy-saving operating mode where airflow and conditioning are reduced during periods of low activity while still maintaining defined limits. It is typically used when production is paused or reduced, and it must be set up so cleanliness and pressure requirements remain controlled.

What is a digital twin in cleanroom design, and what problem does it solve?

A digital twin is a simulation model used before construction to predict airflow behavior and pressure performance. It helps set air change rates and design parameters more accurately, reducing the risk of overdesign and avoiding unnecessary energy use built into the system from day one.

What energy savings are realistic for an energy-efficient cleanroom upgrade or new build?

Savings depend on the baseline design, cleanliness class, operating hours, and how the HVAC and envelope are configured. In many cases, the biggest gains come from reducing pressure losses, improving airtightness, and using dynamic control strategies instead of fixed airflow setpoints.

Does energy efficiency conflict with GMP or ISO cleanroom compliance?

No. Energy efficiency and compliance can work together when the cleanroom is designed to meet performance requirements with better control and lower losses. The key is to define acceptance criteria clearly and validate the operating modes and control strategy.