Speed within CTO+

Fast cleanroom delivery without compromising performance or compliance.

We deliver validated cleanroom solutions using proven ADAPTUS building blocks and a Configure-to-Order Plus approach, allowing faster installation, predictable timelines, and consistent quality.

The problem of traditional approach

Traditional cleanroom delivery relies on an Engineer-to-Order model. This method is slow, resource-heavy, and prone to delays. Each project starts as a unique design, similar to building a custom facility from scratch every time.

As a result, this approach often leads to:

-

Extended engineering cycles

-

Delayed market entry

-

Higher technical and commercial risk

In today’s market, speed and reliability define success. Therefore, the Engineer-to-Order model is no longer a sustainable option.

Our Solution: Speed through validated building blocks

By moving from Engineer-to-Order to Configure-to-Order, we change how modular cleanrooms are delivered. This approach uses standardized, pre-engineered, and validated building blocks to create solutions that meet daily operational needs.

As a result, timelines shrink while performance, compliance, and flexibility remain intact. In addition, the approach avoids unnecessary redesign and repeated engineering work.

How We Deliver Speed

Standardized building blocks

We design cleanrooms using a predefined portfolio of ADAPTUS modules. These modules contain proven design logic and validated data. Consequently, engineering time is reduced, and continuous improvement becomes possible across projects.

Parallel configuration

Predefined building blocks allow configuration and engineering to run in parallel. This significantly shortens lead times. Moreover, with key materials in stock, execution can start as soon as the configuration is approved.

Fast installation, right the first time

Standardized components simplify on-site installation. Clear interfaces reduce complexity and limit errors. As a result, teams achieve right-first-time execution and avoid rework or late design changes.

Your competitive advantage

Adopting Configure-to-Order is not simply a technical decision; it is a strategic advantage. The configured approach delivers tangible improvements across time-to-market, validation effort, and ability to expand over time.

Advantage for you

Mechanism

Impact

Faster time-to-market

Pre-engineered modules

Delivery timelines up to 50% shorter than traditional projects (8–12 weeks)

Simplified validation and compliance

Proven, tested components

Faster CQV and reduced risk of rework during commissioning and validation

Ability to expand

Modular building blocks

Future expansion and adaptation without redesign, protecting your investment

Choose your configuration

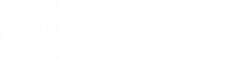

ICONIC addresses the growing demand for quick and efficient cleanroom solutions. In fact, it is the ideal entry-level option for a wide range of applications.

Classifications

Up to ISO6

Location

Indoor

Price range

Delivery times

6-8 weeks

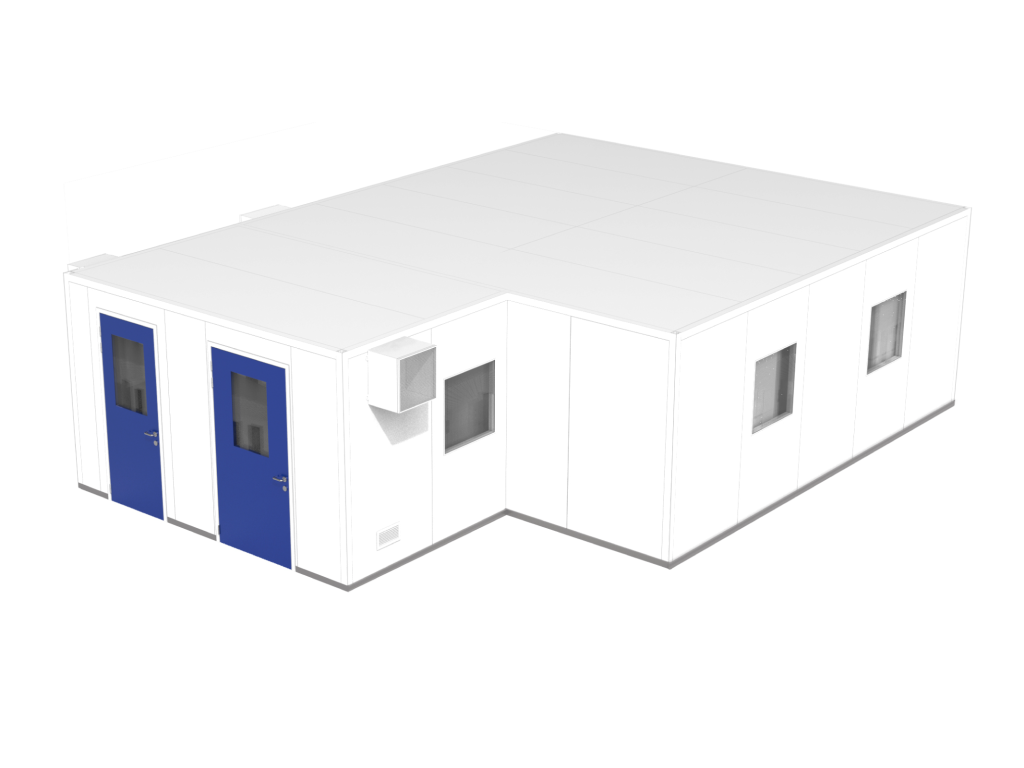

INTEGRA is a modular, off-the-shelf cleanroom solution. It meets ISO and cGMP standards through the integrated VIX concept. Moreover, it provides strong compliance without long lead times.

Classifications

Up to ISO5

Up to cGMP B

Location

Indoor

Price range

Delivery times

10-15 weeks

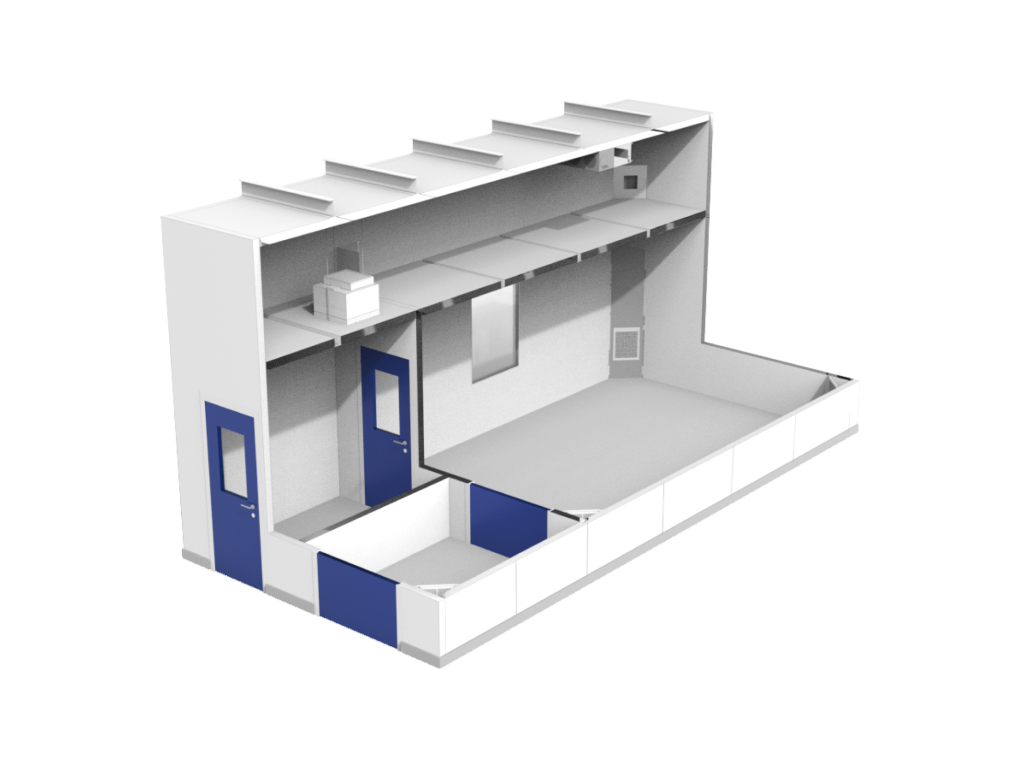

STERICUBE ONE

SteriCube ONE is a modular outdoor cleanroom unit. Therefore, it is ideal when indoor space is limited but controlled environments are still required.

Classifications

Up to ISO5

Up to cGMP B

Location

Outdoor

Price range

Delivery times

12-16 weeks

Start your cleanroom project

Tell us about your cleanroom requirements and specifications, and we’ll prepare a first cost estimation for you within one working day. Simply complete the form with as much detail as possible, from classification and size to specific industry or technical needs.

Prefer to speak directly? You can always contact us by phone or email, and our team will be happy to discuss your project.

FAQ

The most frequently asked questions about our custom cleanroom solutions.

What does Configure-to-Order (CTO) mean for cleanrooms?

Configure-to-Order means building a cleanroom using pre-engineered, validated building blocks instead of designing everything from scratch. The cleanroom is configured to project requirements using proven modules, which reduces engineering time, risk, and delivery lead time.

How is Configure-to-Order different from Engineer-to-Order (ETO) cleanrooms?

Engineer-to-Order cleanrooms are custom-designed for each project, which leads to long engineering phases, higher risk, and unpredictable timelines. Configure-to-Order cleanrooms use standardized, validated modules, allowing faster configuration, parallel engineering, and more predictable delivery.

How fast can a Configure-to-Order cleanroom be delivered?

Because engineering, configuration, and execution run in parallel, Configure-to-Order cleanrooms can typically be delivered in 8 to 12 weeks, depending on scope and configuration. This is often up to 50 percent faster than traditional approaches.

Are Configure-to-Order cleanrooms compliant with GMP and ISO standards?

Yes. Configure-to-Order cleanrooms are built from pre-engineered and validated components. This simplifies commissioning, qualification, and validation while supporting compliance with GMP and ISO cleanroom standards.

Can a Configure-to-Order cleanroom be expanded or modified later?

Yes. Configure-to-Order cleanrooms are modular by design. Additional capacity, new zones, or layout changes can be added using the same standardized building blocks, protecting the original investment.

What types of industries benefit most from Configure-to-Order cleanrooms?

Industries that value speed, predictability, and compliance benefit most. This includes pharmaceuticals, biotechnology, cell and gene therapy, medical devices, and advanced semiconductor manufacturing.

Does Configure-to-Order reduce project risk?

Yes. By using tested, repeatable building blocks, Configure-to-Order removes many design and execution risks associated with one-off engineering. This reduces rework, delays, and unexpected changes during the project.

Is Configure-to-Order suitable for high-performance or complex cleanrooms?

Yes. Configure-to-Order does not limit performance or complexity. It standardizes the building blocks while allowing configuration flexibility to meet specific process, performance, and compliance requirements.