Reliability Within CTO+

Guaranteed uptime: engineered for 99.995% reliability

We deliver cleanroom solutions built on verified, repeatable modules and continuous digital monitoring to ensure stable performance and protect mission-critical operations.

The problem: traditional reliability risks

Conventional, custom-designed (Engineer-to-Order) cleanrooms introduce unnecessary risks, high costs, and downtime.

- Risk of Failure: Because every traditional cleanroom is a completely new design, errors and failures are common.

- Maintenance Downtime: Traditional systems lack redundancy. If the central AHU or main ductwork fails, the entire cleanroom shuts down.

- Compliance Uncertainty: Traditional designs start from scratch. Components are not pre-validated. This extends qualification timelines and increases compliance risk.

Our solution: repeatable, verified technology

We ensure reliability by replacing custom designs with a configured, modular cleanroom approach. Proven modules and digital control reduce risk and improve system stability. Quick-Look Features:

- Redundancy: Redundancy of critical mechanical components is embedded in the system design, ensuring up to 99.995% operational uptime.

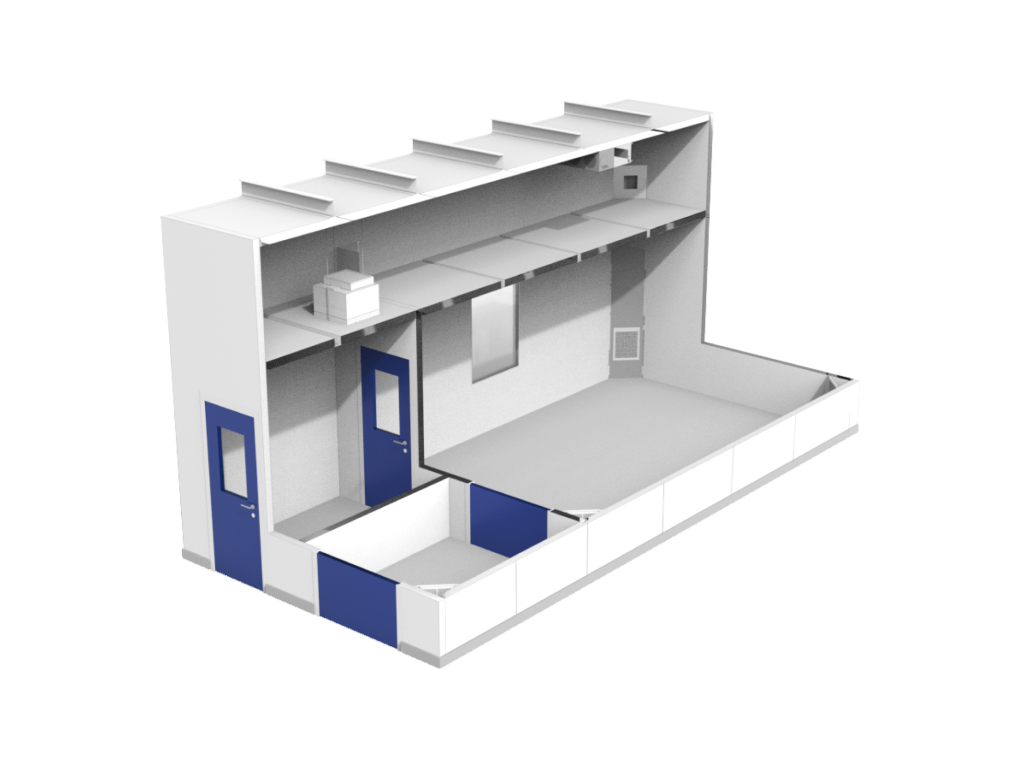

- Non-Intrusive Maintenance: ABN patented VIX decentralized air system is maintained remotely from the technical zone, guaranteeing zero downtime and reducing contamination risk. Its modular design provides built-in redundancy, ensuring the cleanroom keeps running even if one unit requires service.

- Digital Monitoring: ABN’s CleanConnect and GMPConnect systems provide continuous, real-time data insights. This enables predictive maintenance, guaranteeing 99.995% system uptime.

Your competitive advantage

Our configuration approach provides confidence in your schedule, compliance, and long-term operation:

Advantage for you

Mechanism

Impact

Guaranteed uptime

Digital monitoring and VIX system

System availability up to 99.995%

Faster compliance and validation

Pre-tested ADAPTUS modules

Shorter CQV timelines while maintaining ISO and cGMP requirements

Zero production stops during maintenance

Non-intrusive maintenance

Servicing without entering the production area

Choose your configuration

INTEGRA is a modular, off-the-shelf cleanroom solution. It meets ISO and cGMP standards through the integrated VIX concept. Moreover, it provides strong compliance without long lead times.

Classifications

Up to ISO5

Up to cGMP B

Location

Indoor

Price range

Delivery times

10-15 weeks

The VIX concept is an integrated airflow and plenum solution designed to ensure ISO and cGMP compliance. It combines high performance with energy efficiency, providing reliable cleanroom conditions without complex construction or long lead times.

Classifications

Up to ISO 4

Up to cGMP A

Location

Indoor

Price range

Delivery times

16 weeks

Start your cleanroom project

Tell us about your cleanroom requirements and specifications, and we’ll prepare a first cost estimation for you within one working day. Simply complete the form with as much detail as possible, from classification and size to specific industry or technical needs.

Prefer to speak directly? You can always contact us by phone or email, and our team will be happy to discuss your project.

FAQ

The most frequently asked questions about our custom cleanroom solutions.

Why do traditional cleanrooms experience more downtime?

Traditional Engineer-to-Order cleanrooms are unique designs. This increases engineering variability, interfaces, and site changes, which can lead to failures, rework, and longer recovery time when something goes wrong.

What does “99.995% reliability” mean in practice?

It means the cleanroom is designed to stay operational with extremely high availability. The goal is to prevent single failures from causing a shutdown and to detect issues early so maintenance can be planned instead of disruptive.

What is redundancy in a cleanroom, and why does it matter?

Redundancy means the cleanroom has backup capacity or distributed systems so a single failure does not stop operations. It matters because many cleanrooms lose production when a central unit or main ductwork fails.

How does a configured, modular cleanroom improve reliability?

A configured, modular cleanroom uses repeatable, pre-engineered modules. This reduces design risk, shortens commissioning effort, and improves operational stability because systems behave consistently across deployments.

How does non-intrusive maintenance reduce downtime and contamination risk?

Non-intrusive maintenance allows service work to be performed from technical areas rather than inside the controlled production zone. This reduces disruption to production and lowers the risk introduced by technicians entering the cleanroom during maintenance.

What is the role of digital monitoring in reliability?

Digital monitoring provides continuous, real-time data on system status and performance. This supports predictive maintenance and faster troubleshooting, which reduces unplanned downtime and improves availability.

Does higher reliability also simplify qualification and compliance?

Yes. When key components are pre-tested and repeatable, commissioning, qualification, and validation become more straightforward. This reduces rework and helps maintain consistent performance in line with ISO and cGMP expectations.

What information do you need to assess reliability requirements for a project?

Typical inputs include cleanliness class, process criticality, uptime targets, operating schedule, maintenance constraints, and any compliance requirements. These define what redundancy, monitoring, and service access are needed.