Budget within CTO+

The price you control

Our modular cleanroom solutions are based on a Configure-to-Order approach, enabling a fixed price upfront and reducing lifetime financial risk by avoiding hidden costs.

The problem of traditional approach

Traditional custom-built cleanrooms are at their core high-risk, often leading to significant financial losses over time.

- Inflated Investment (CAPEX): Without value engineering, custom designs often include unnecessary features. This leads to over-engineering and higher initial investment.

- No Budget Flexibility: Because each design is a one-off, clients cannot easily adjust scope to control costs or meet budget targets.

- Cost Overruns: Without standardized modules, issues found during execution require re-engineering. This leads to unexpected costs and budget overruns.

Our Solution: Price is managed by configuration

We reduce financial risk and provide price certainty. Clients control cost directly through our configured, value-engineered approach. Quick-Look Features:

- Guaranteed Cost Control: Value engineering is built in from the start. ADAPTUS building blocks ensure you pay only for the functions you need. You configure the cleanroom to meet your need and budget.

- Optimized Lifetime Cost: Our design minimizes complexity to achieve the Lowest Total Cost of Ownership (TCO), drastically reducing long-term energy consumption and operating costs (OPEX).

- Reduced Construction Time: Our configure-to-order system dramatically cuts on-site installation time, resulting in reduced project management costs.

Your competitive advantage

Our configuration approach provides confidence in your budget and minimizes the lifetime financial risk:

Advantage for you

Mechanism

Impact

Guaranteed CAPEX control

Value engineering and ADAPTUS platform

Pricing is defined by the selected components and scope.

Lowest OPEX

Patented VIX decentralized system

Improved energy efficiency and support for dynamic night setback operation.

Choose your configuration

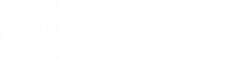

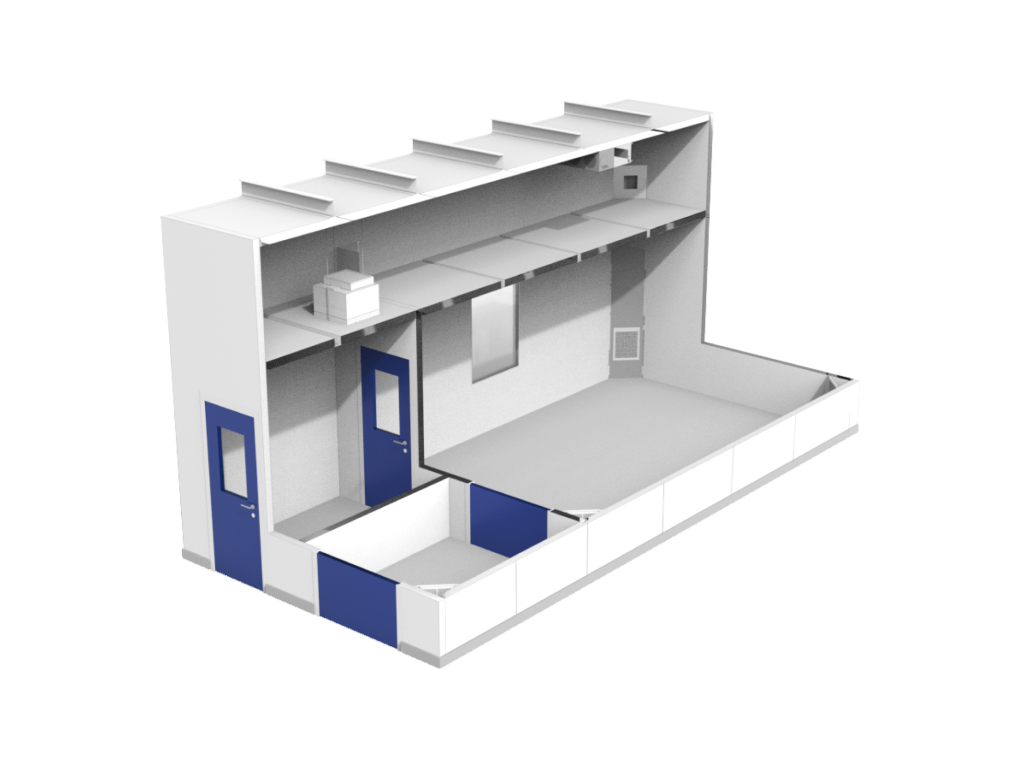

ICONIC addresses the growing demand for quick and efficient cleanroom solutions. In fact, it is the ideal entry-level option for a wide range of applications.

Classifications

Up to ISO6

Location

Indoor

Price range

Delivery times

6-8 weeks

INTEGRA is a modular, off-the-shelf cleanroom solution. It meets ISO and cGMP standards through the integrated VIX concept. Moreover, it provides strong compliance without long lead times.

Classifications

Up to ISO5

Up to cGMP B

Location

Indoor

Price range

Delivery times

10-15 weeks

Start your cleanroom project

Tell us about your cleanroom requirements and specifications, and we’ll prepare a first cost estimation for you within one working day. Simply complete the form with as much detail as possible, from classification and size to specific industry or technical needs.

Prefer to speak directly? You can always contact us by phone or email, and our team will be happy to discuss your project.

FAQ

The most frequently asked questions about our custom cleanroom solutions.

What does “Cleanrooms Configured for Budget” mean?

It means the cleanroom scope, components, and performance are defined upfront using a Configure-to-Order approach. This allows pricing to be set early and controlled through configuration instead of changing later through custom redesigns.

How does Configure-to-Order enable fixed pricing for cleanrooms?

Configure-to-Order uses standardized, pre-engineered building blocks with known costs and performance. Because the scope is configured rather than designed from scratch, pricing can be defined upfront and remains stable throughout the project.

Why do traditional cleanroom projects often exceed budget?

Traditional custom cleanrooms are engineered uniquely for each project. During execution, design changes, coordination issues, and late discoveries often require re-engineering, which leads to cost overruns and unplanned expenses.

What is value engineering in a cleanroom project?

Value engineering means designing the cleanroom to include only the functions required to meet performance and compliance needs. It avoids unnecessary features that increase CAPEX without adding operational value.

How does configuration reduce lifetime financial risk?

Configuration reduces financial risk by limiting design uncertainty, avoiding late changes, and improving predictability during construction and operation. This lowers the risk of both CAPEX overruns and higher-than-expected OPEX.

What is Total Cost of Ownership (TCO) in a cleanroom?

Total Cost of Ownership includes the initial investment, energy use, maintenance, and operating costs over the cleanroom’s lifetime. A configured cleanroom is designed to reduce complexity and energy demand, lowering overall TCO.

Does faster construction also reduce project cost?

Yes. Shorter construction and installation time reduces project management effort, site labor, and coordination costs. This contributes directly to lower overall project cost.