A company’s records are a prized possession and should be taken care of the best way possible. When we think of good manufacturing practices (GMP), regulations must be followed to keep the quality and integrity of these records in good standing. Records are official evidence proving that certain tasks have been completed as they should be –evidence of compliance– and poorly documenting can negatively impact cleanroom process quality. In this article, we’ll shortly discuss paper records vs. electronic records for GMP processes.

These days, the majority of companies offering GMP cleanroom validation services uses paper records. Although paper records allow a clear visible error correction, it can sometimes be hard to tell the reason for a correction. Paper recording means no messing around with local software configurations on your computer or computer validation to worry about. Also the fact that paper is a relatively robust medium with less risk of data loss if environmental conditions are maintained and controlled can be seen as an advantage.

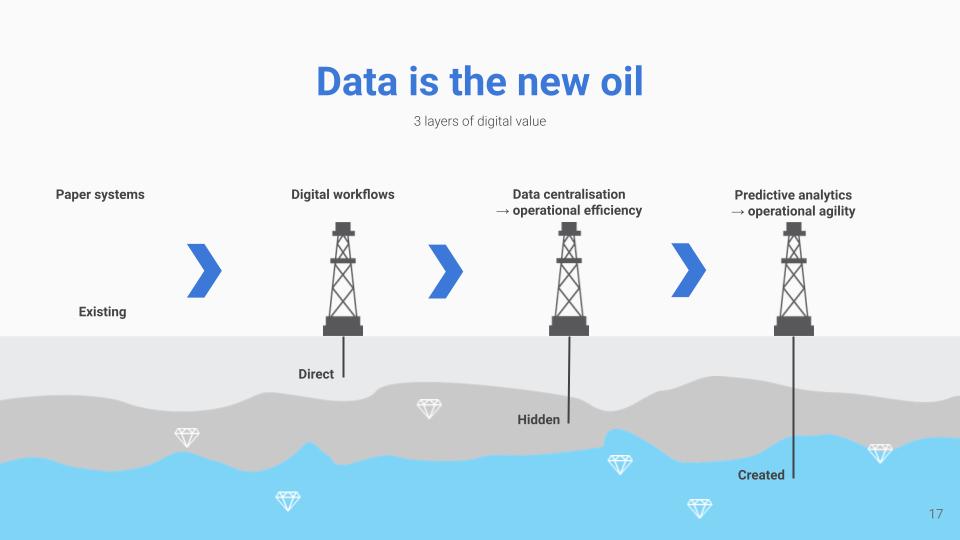

On the other hand, it is no secret that paper recording comes with several disadvantages, such as human errors, limited search capabilities -EU GMP requires certain analytical data trending, which can hardly be realized with paper records- and the unsustainable way of storing papers in appropriate environmental conditions. For these and many more reasons, we decided that it’s worth digitizing our GMP cleanroom validation process.

ABN Cleanroom Technology is specialized in cleanroom validation activities for cGMP and ISO14644 compliant facilities. Throughout the years, we have obtained much experience and knowledge to support customers in validating all sorts of critical areas, ranging from cleanrooms, to LAF cabinets and ATMP environments. Digitizing our GMP validation flow results in increased work quality at higher pace by our validation engineers. Moreover, our cooperation with MyCellhub for this digitization process leads to:

Data integrity and traceability of recordings is of the utmost importance. Paper-based records require you to manually copy data and enter it into an informatics application. This is a slow, tedious and error-prone process. A digitized GMP validation process saves a lot of time for validation engineers, reduces human actions and thus human errors.

Our highly trained validation engineers are often wasting precious time copying data from paper-based records to an excel file or BI system in order to generate data reports. During this type of tedious data manipulations, human errors may occur. In our digitized GMP validation process, the operator enters the data once and automatically generates reports.

Legolisation means standardisation. Standardisation causes a shift in production. Work is carried out in conditioned spaces such as factory halls. our cleanrooms are manufactured partly or entirely off-site, which means huge savings on transport costs and reduction of inconvenience on-site