blog

Continuous particle monitoring in cleanrooms: a no-brainer when it comes to energy saving

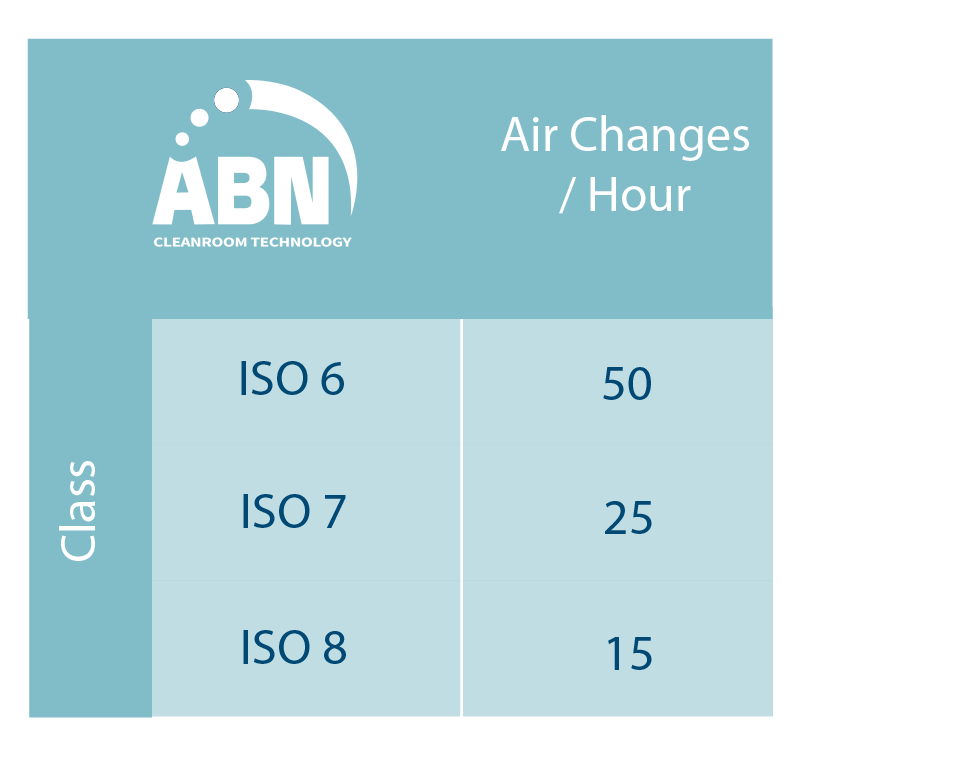

As a result of rising energy prices, we notice that many cGMP and non-cGMP companies are considering installing a continuous particle counter in their cleanroom. Since continuous particle counting within cGMP is only a requirement in Grade B and Grade A environments, it didn’t happen often in other cleanroom environments until today. Companies are finding that the investment cost of an online particle counting system pays for itself very quickly and opt for this interesting investment. A shift in the cleanroom world that is fully in line with our patented VIX concept and which we therefore completely approve.